The Institute for Advanced Architecture of Catalonia (IAAC) has completed the 3D printing of a 100 m² low carbon emissions building prototype using local soil and natural materials. Situated in the Natural Park of Collserola (Barcelona), the project utilizes the Crane WASP 3D printer, advancing towards KM0 affordable housing models.

Collaborating with global architecture firm Hassell, the project started as a 3D-printed earth wall prototype, intended for a future project in Tanzania. Initially funded by Hassell, IAAC expanded the prototype into a full-scale pavilion.

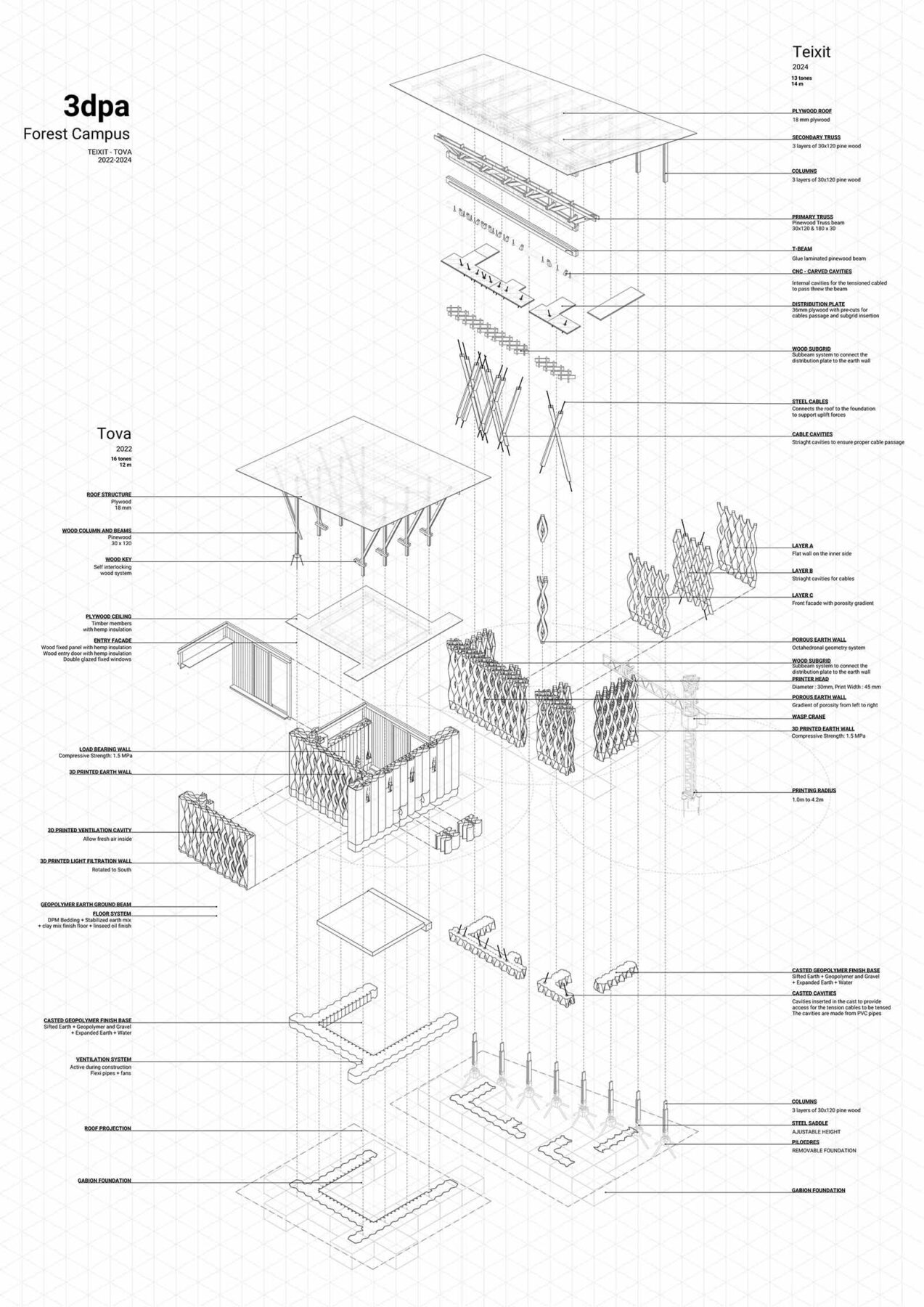

The 3D-Printed Forest Campus is an intervention featuring enclosed and open spaces made from 3D-printed earth. It serves as a laboratory, testing construction techniques and architectural solutions.

The fragmented floorplan reflects design flexibility accommodated by 3D printing, with the layout evolving over time. Wall sections were printed, torn down, and recycled into new structures. The project’s spatial distribution creates a multitude of rooms, perspectives, and environments—indoor, semi-indoor, and outdoor—it distances itself from standardized architecture and adapts to user needs.

The 3D-Printed Forest Campus is made from material sourced a few meters away: excavated from below 0,5m to avoid organic content, the earth is sun-dried sieved, mixed with water, added organic fiber and natural enzyme until pressed into the printer.

Below the ground, a 50cm natural stone foundation ensures stability and drainage, while the first 30 cm of the walls consist of a solid 40-70 cm thick stabilized earth base to protect from floods.

The walls are printed at a rate of 25 cm per day to prevent collapse from self-weight, reaching 2.5 meters in 10 days.

As the walls dry, roofs are installed and anchored to prevent wind uplift, sometimes with steel cables for post-tensioning.

Unlike typical masonry, the printed walls are 50% hollow, with cavities reducing material usage and enabling the integration of insulation, services, and ventilation. Wall thickness ranges from 40 – 70 cm, depending on the structural load.

While earth constructions result in thick, opaque walls due to low mechanical strength, additive manufacturing allows for lighter, porous walls with 20 cm wide openings, using layered construction and localized cantilevers.

The first phase of the 3D-Printed Earth Forest Campus (TOVA) was awarded the “Shaping a circular industrial ecosystem” prize at the New European Bauhaus in 2023”. TEIXIT extends the living and working area of the campus.

Facts & Credits

Title 3D-Printed Forest Campus

Typology Architecture, Laboratory

Location Natural Park of Collserola, Barcelona, Spain

Status Completed, 2024

Directors Edouard Cabay & Alexandre Dubor

Coordinator Yara Tayoun

Faculty 23/24 Oriol Carrasco (Senior Fabrication Expert), Elisabetta Carnevale (Material Expert), Alicia Huguet (Structural Expert – SOCOTEC Spain)

Faculty Assistants 23/24 Secil Afsar (Fabrication Assistant, Material Research Expert), Nestor Beguin (Computational Expert)

Collaborators WASP (Large Scale 3D printing), SOCOTEC (Structural Consultant), Hassell (Global Architecture Studio), Vervictech (Enzymes provider), Colette (philanthropic organisation)

Researchers 23/24 Jose Antonio Gutierrez Rangel, Joseph Milad Wadie Naguib, Justin Hanlon, M´Hamed Alila, Maria Kaltsa, Mark Francis, Noel Akroma, Sakshi Pawar, Sara Ayoub, Vesela Tabakova, Yang Xiao

Researchers 21/22 Adel Alatassi, Aslinur Taskin, Charles Musyoki, Deena El-Mahdy, Eugene Marais, Hendrik Masjosthusmann, Juliana Rodriguez Torres, Leonardo Bin, Mariam Arwa Al-Hachami, Marwa Abdelrahim, Mehdi Harrak, Michelle Bezik, Michelle Antonietta Isoldi Campinho, Mouad Laalou, Nareh Khaloian Sarnaghi, Nawaal Saksouk, Orestis Pavlidis, Seni BoniDara

Special thanks Areti Markopoulou, Mathilde Marengo, Daniel Ibanez, Ricardo Mayor, Shyam Zonca, Sheikh Riaz, Philip Wienkamper, Pilar Xiquez, Daniela Figueroa Claros, Jorge Ramirez, Massimo Visiona, Massimo Moretti, Francesca Moretti, Laia Pifarre, Bruno Ganem, Xavier de Kestelier

Photography IAAC/3DPA & Iwan Baan

Text by IAAC

Το Institute for Advanced Architecture of Catalonia (IAAC) ολοκλήρωσε την τρισδιάστατη εκτύπωση ενός πρότυπου κτιριακού συμπλέγματος κλειστών και ημιυπαίθριων χώρων, με την τεχνολογία ‘‘CRANE WASP 3D’’.

Το έργο βρίσκεται στην περιφέρεια της Βαρκελώνης καλύπτοντας 100 τ.μ. Για την κατασκευή αξιοποιείται τοπικό χώμα και φυσικά υλικά , προτείνοντας οικιστικές λύσεις KM0.

Η πρώτη φάση (TOVA) περατώθηκε το 2022 ενώ η δεύτερη (TEIXIT) το 2024. Η μελέτη της επέκτασης πραγματοποιήθηκε σε συνεργασία με το αρχιτεκτονικό γραφείο Hassel για το σχεδιασμό κοινοτικού κτιρίου στην Τανζανία.

Το 3D-Printed Forest Campus είναι μια παρέμβαση που λειτουργεί ως εργαστήριο για τη δοκιμή κατασκευαστικών τεχνικών. Ο κατακερματισμός του σε επιμέρους τμήματα αποσκοπεί στην σταδιακή εξάπλωση μέσω της προσθήκης τοίχων, περικλείοντας χώρους διαφορετικών παραμέτρων και ποιοτήτων.

Στοιχεία έργου

Τίτλος 3D-Printed Forest Campus

Τυπολογία Αρχιτεκτονική, Εργαστήριο

Τοποθεσία Natural Park of Collserola, Βαρκελώνη, Ισπανία

Κατάσταση Ολοκληρωμένη, 2024

Υπεύθυνοι Έργου Edouard Cabay & Alexandre Dubor

Συντονίστρια Yara Tayoun

Τμήμα 23/24 Oriol Carrasco (Senior Fabrication Expert), Elisabetta Carnevale (Material Expert), Alicia Huguet (Structural Expert – SOCOTEC Spain)

Βοηθοί Τμήματος 23/24 Secil Afsar (Fabrication Assistant, Material Research Expert), Nestor Beguin (Computational Expert)

Συνεργάτες WASP (Large Scale 3D printing), SOCOTEC (Structural Consultant), Hassell (Global Architecture Studio), Vervictech (Enzymes provider), Colette (philanthropic organisation)

Ερευνητικό προσωπικό 23/24 Jose Antonio Gutierrez Rangel, Joseph Milad Wadie Naguib, Justin Hanlon, M´Hamed Alila, Maria Kaltsa, Mark Francis, Noel Akroma, Sakshi Pawar, Sara Ayoub, Vesela Tabakova, Yang Xiao

Ερευνητικό προσωπικό 21/22 Adel Alatassi, Aslinur Taskin, Charles Musyoki, Deena El-Mahdy, Eugene Marais, Hendrik Masjosthusmann, Juliana Rodriguez Torres, Leonardo Bin, Mariam Arwa Al-Hachami, Marwa Abdelrahim, Mehdi Harrak, Michelle Bezik, Michelle Antonietta Isoldi Campinho, Mouad Laalou, Nareh Khaloian Sarnaghi, Nawaal Saksouk, Orestis Pavlidis, Seni BoniDara

Ευχαριστίες Areti Markopoulou, Mathilde Marengo, Daniel Ibanez, Ricardo Mayor, Shyam Zonca, Sheikh Riaz, Philip Wienkamper, Pilar Xiquez, Daniela Figueroa Claros, Jorge Ramirez, Massimo Visiona, Massimo Moretti, Francesca Moretti, Laia Pifarre, Bruno Ganem, Xavier de Kestelier

Φωτογραφία IAAC/3DPA & Iwan Baan

Κείμενο IAAC

READ ALSO: Ecokinesthetic neighbourhoods | Diploma thesis project by Lydia Panagoulia