During FALL 2019 the Architecture Department ARC of the University of Nicosia has launched a New Distance Learning MSc Programme in Computational Design and Digital Fabrication in collaboration with the University of Innsbruck, Institute for Experimental Architecture Hochbau in Austria.

The programme aims at exploring the relationship between computational tools and architectural design, in an effort to attain a new insight into the relationship between design intent and built form. Within this scope the participants have the opportunity to develop computational design skills and acquire hands-on cutting-edge fabrication experiences, while cultivating analytical and creative thinking on the applications of computation in design.

The curriculum is uniquely structured to combine distance learning education with face to face learning. Each Academic Semester concludes with a digital fabrication workshop were participants are invited to visit University of Nicosia F-Lab and University of Innsbruck, Robotic Lab (REXLAB) respectively to participate in an intensive two-week workshop with a thematic that changes every year depending on the overall programme brief, interests of faculty and visiting specialists.

These intensive courses add flexibility to the curriculum, encourage the development of a hands-on collaborative culture and provide a productive close to the semester. With these workshops in place, the faculty are able to respond to newly developing research or design practices offering motivating and exciting opportunities to the students. A series of parallel events such as visits, discussions, lectures and presentations frame the workshops to enrich the energetic atmosphere and to maximize educational benefits.

The workshop, for FALL semester 2019 was titled testSTEEL8 and run between the 2nd and 13th of December 2019. The focus was on 3D tessellations using sheet metal forming. High-end Industrial CNC Bending and LaserCutting equipment was employed towards digitally fabricating a large scale prototype structure utilizing the participant’s knowledge and skills acquired during the semester.

Furthermore, in an effort to promote sustainable design practices, scrap sheet metal was chosen as construction material. Computational tools and UAVs were implemented for scanning and registering leftover steel parts as to become usable for digital fabrication. Prototyping with both physical and virtual models have driven a process, of real‐time visualization of 3D tessellations, guided by a number of constraints, in order to shape design solutions and evaluate them against their performance.

According to a Department of Architecture tradition, a computationally designed and digitally fabricated X-Mas Tree is proposed, fabricated and assembled just before the winter recess period every year to decorate the department. Departing from previous years and elevated by the current MSc CDDF Workshop the tradition has spread to the main campus of the University of Nicosia.

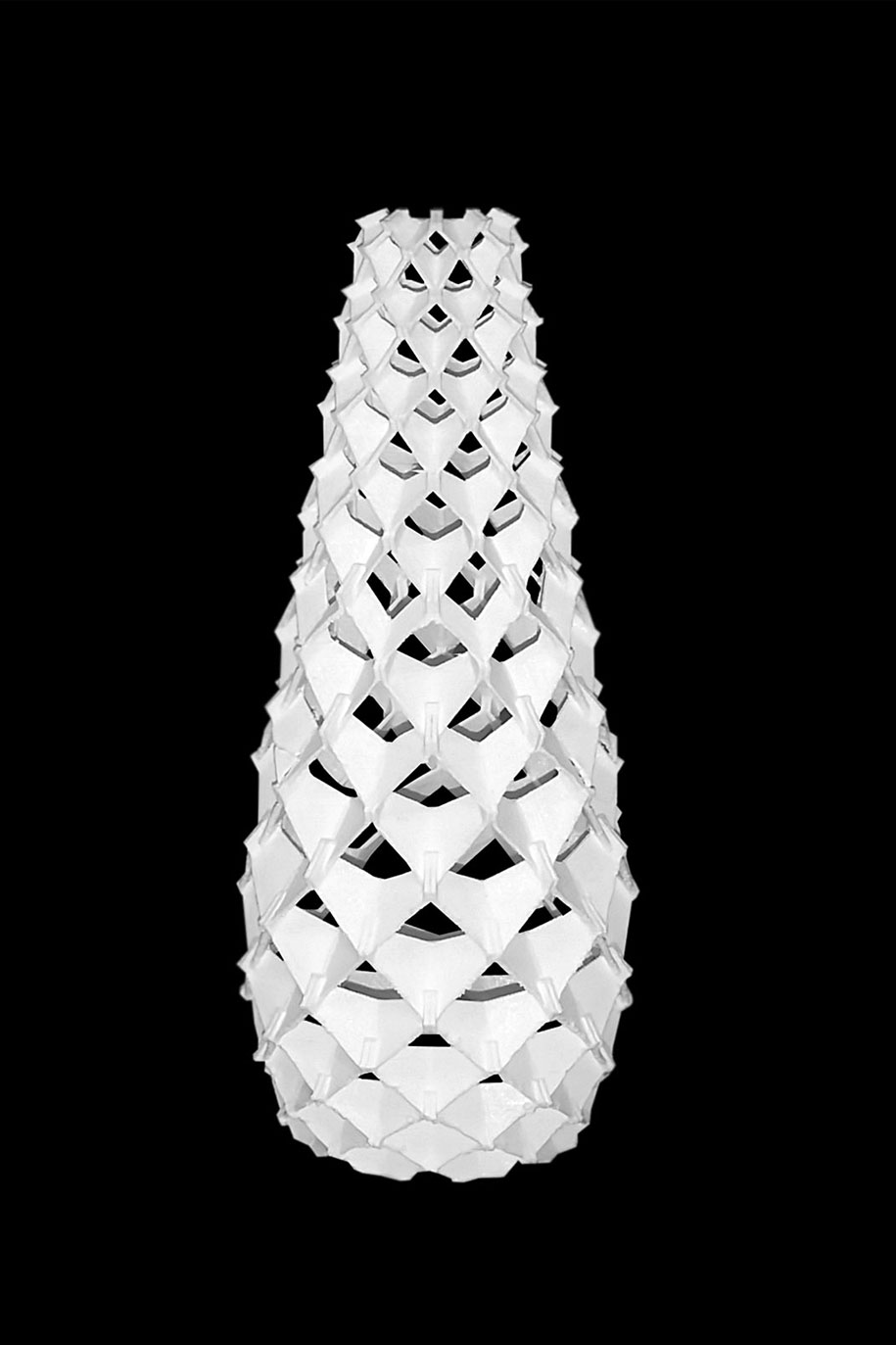

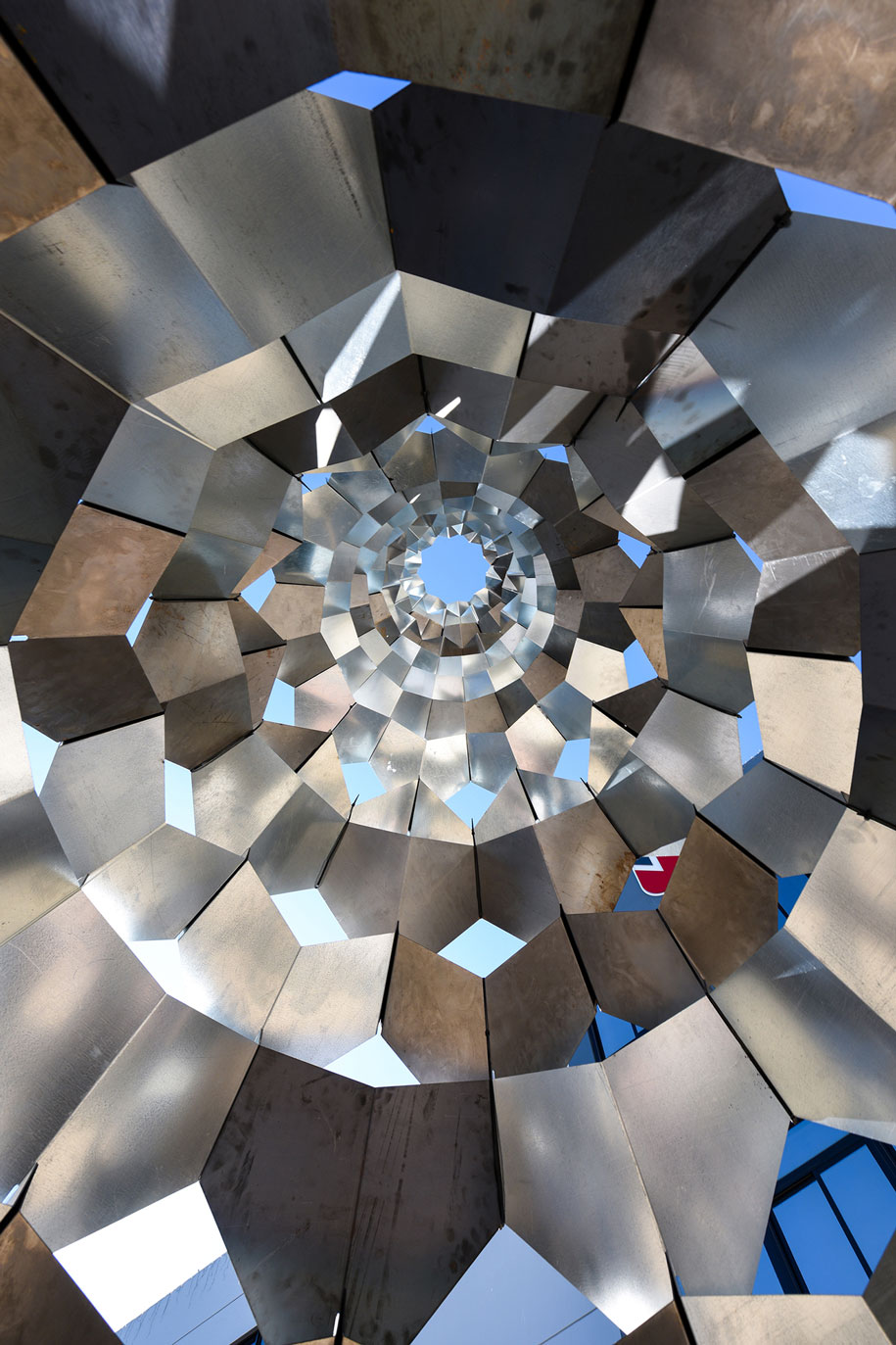

The outcome was dubbed by the students the X-MAX, and was generated by populating a tessellated 3D component using puzzle-like logic on a self-supported doubly-curved surface. 190 unique components were developed into load-bearing modules that could be digitally fabricated out of flat sheets of material and then CNC bend in shape.

The modules were made using galvanised and mild steel of 2mm, 1.5mm and 1mm in thickens, arrayed in an ascending pattern. Once produced, all parts were assembled in a puzzle-like routine to form the structure. During the process, the team had to comply and account for a number of design and fabrication parameters such as material (mild and galvanised steel), thickness, perforations, bends/creases, weave type, assembly methodology and assembly time. The installation weighted 250 kg, its footprint ranged at 2.4m² and its height to 4m. The total cost of fabrication/material used was approximately 1000 €. Assembly time was 8 hours over a period of a day, by a team of ten students.

On exhibition, the parametric installation challenged the visitors’ perception, calling them to explore the qualities of a complex, yet familiar object.

The component-based kaleidoscopic structure constantly adapted to its environment, reflecting the shades of the surroundings and the colours/brightness of the sky. The planned natural corrosion of the untreated mild steel as opposed to the galvanised steel components, will further highlight the ascending pattern formed by the varied materiality while simulating an ageing process for the structure.

X-MAX has been donated to the Municipality of Nicosia and has been relocated to Eleftherias Square, where is currently hosted as a public installation.

You can watch a video about the workshop here.

Team:

Programme Faculty: Michail Georgiou (Coordinator), Pavlos Fereos (Coordinator), Odysseas Georgiou, Eftihis Efthimiou, Doukas Dimitrios

Teaching/Fabrication Assistants: Christina Christoforou

Students: Abdulshafi Alsawadi, Spyros Anatolianos, Abed Badran, Anastasios Balampanidis, Sofia Kakouri, Helia Kasmaei, Kyriakos Kyriakides, Andrea Menardo, Michael Tuttle, Helia Zakeri

Lighting Designer: Kyriaki Paphitou

Photographer: Charis Solomou

Sponsors and Industrial Partners: University of Nicosia, University of Innsbruck, Andreou Laser

READ ALSO: Pezoula Project in south Crete