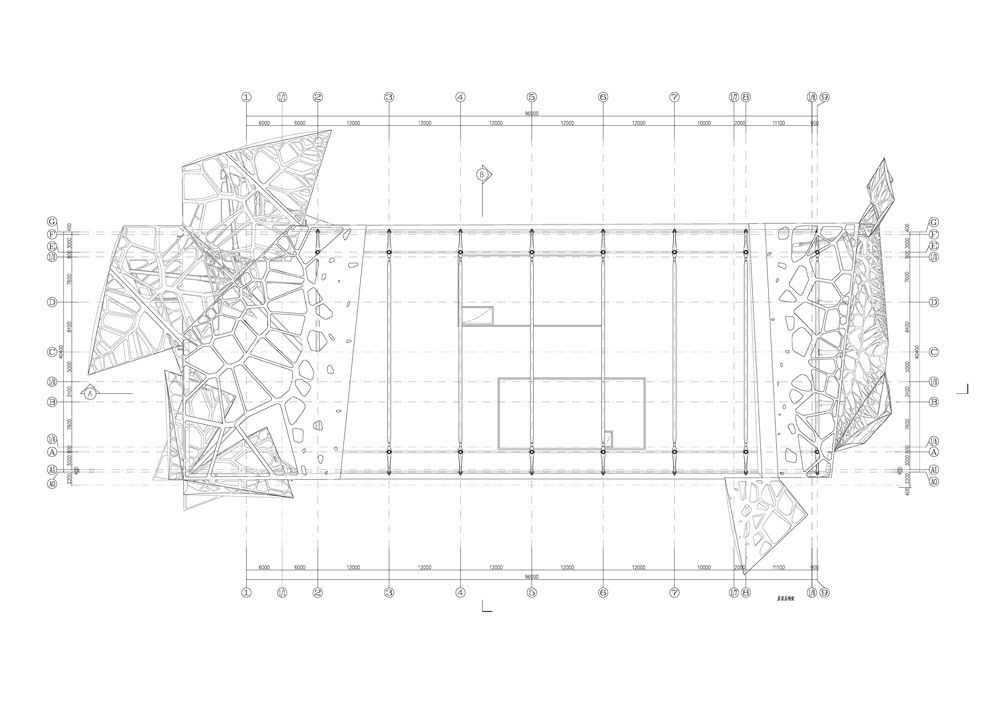

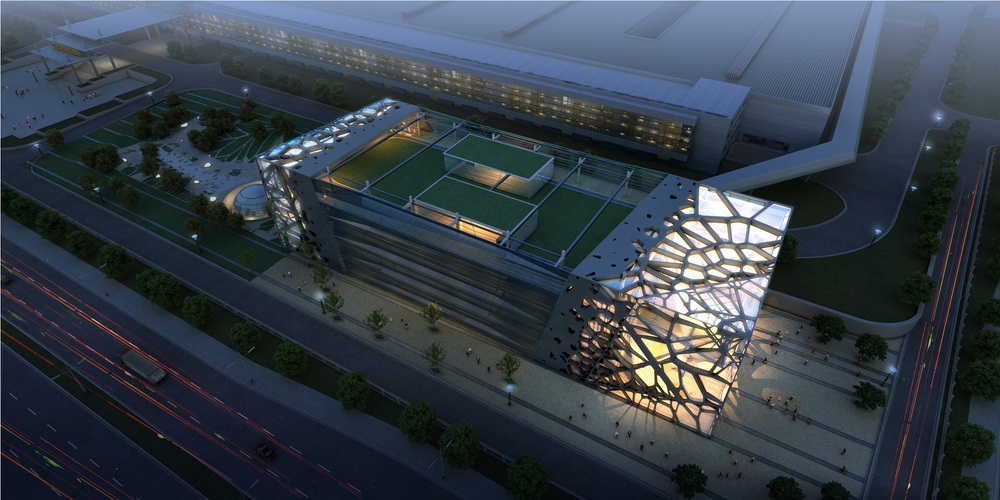

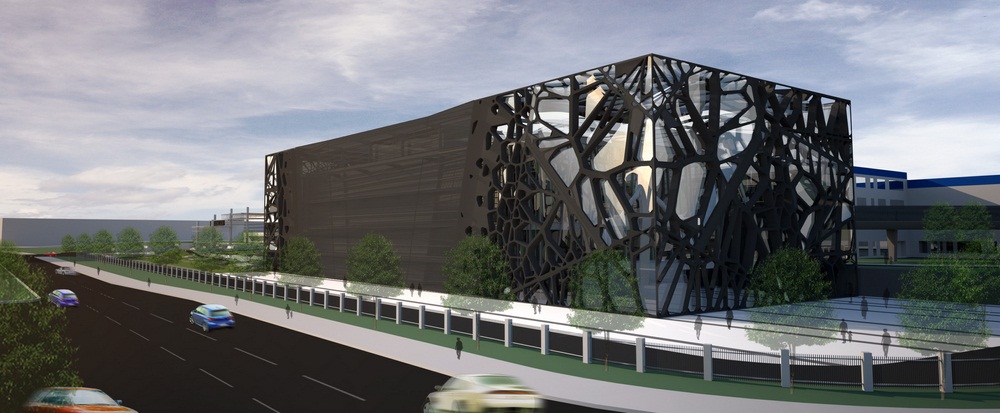

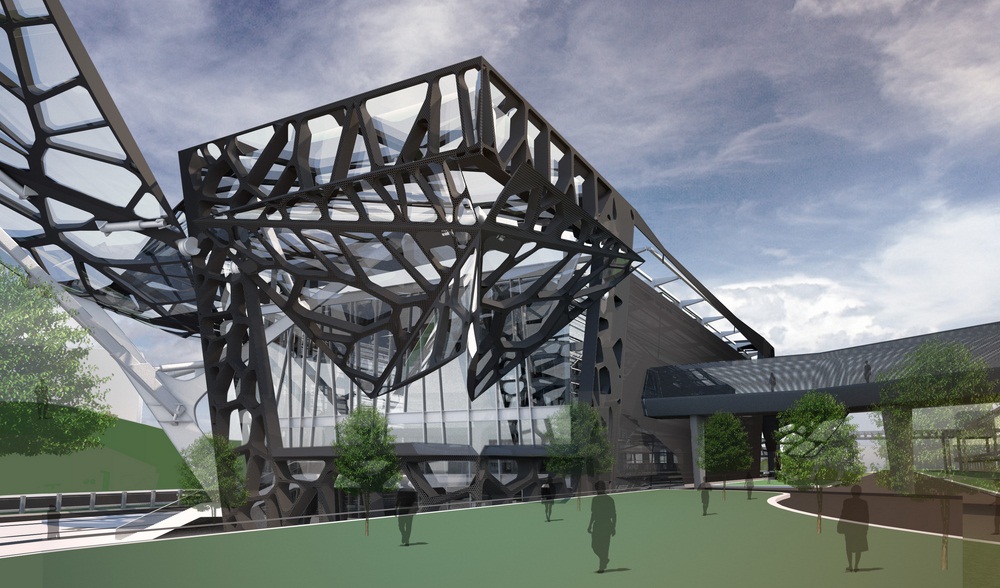

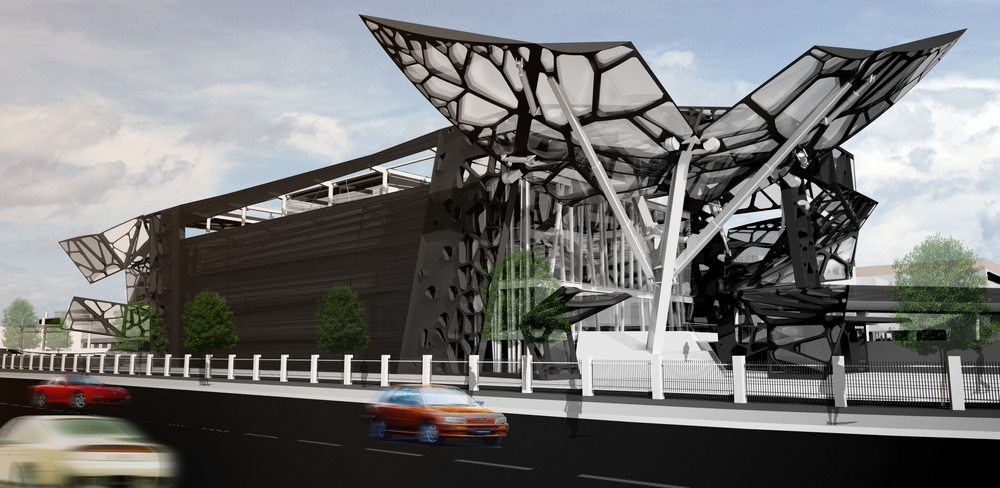

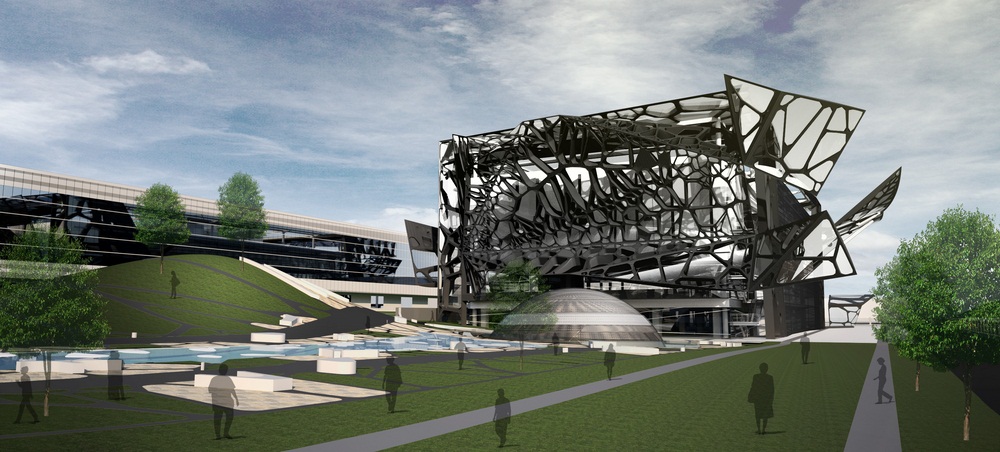

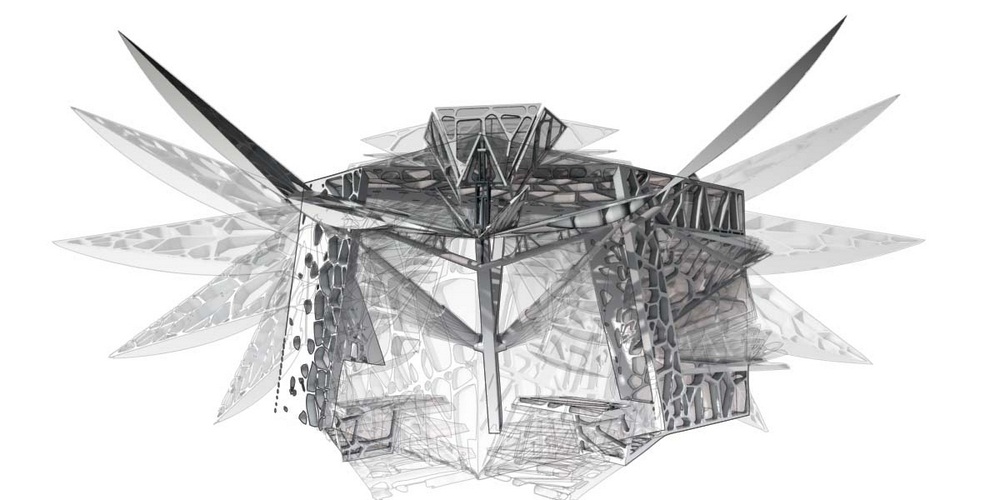

The most unique aspect of our project design is the building’s ability to change shape, or transform, literally. The double skin system throughout the building makes this “transformer building” possible. The inner skin takes care of the enclosure and building systems. The outer skin contains operable portions which can be opened or closed to mimic different animal forms. From a plain rectangular box as the initial state, the north facade transforms into an eagle and a butterfly, the south folds into a swimming frog. These animal forms reflect the company’s understanding of the delicate balance between nature and artificial invention, and their embrace for environmentally sound human development. Also, as a design strategy, we adopted ideographic forms to convey traditional Chinese cultural symbolism for leadership (eagle), ephemerality and fragility (butterfly) and prosperity (toad).

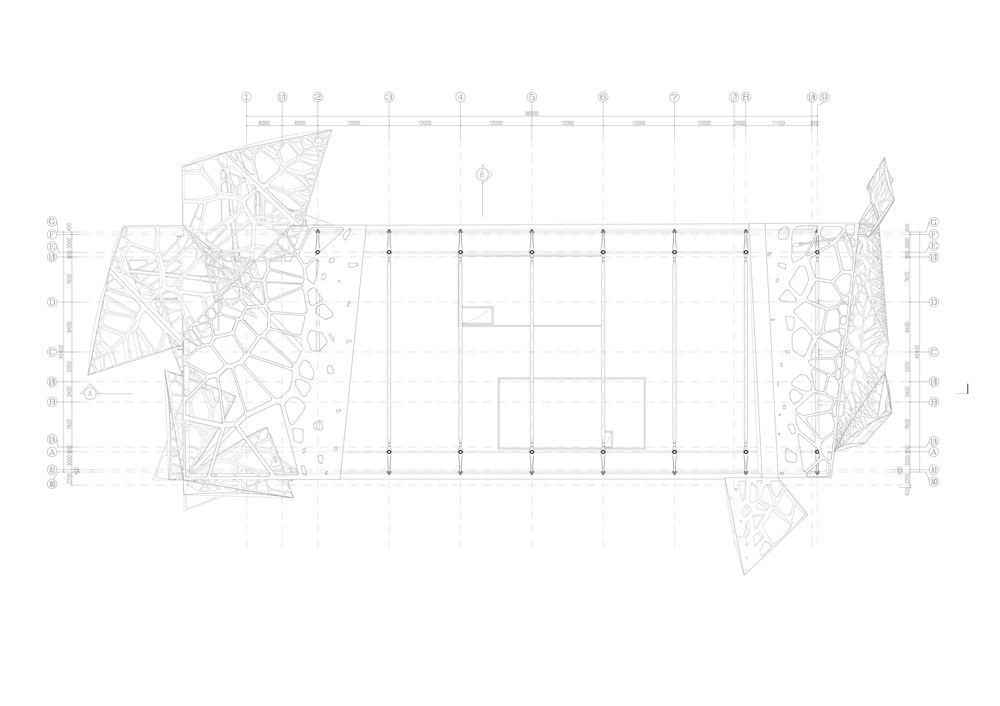

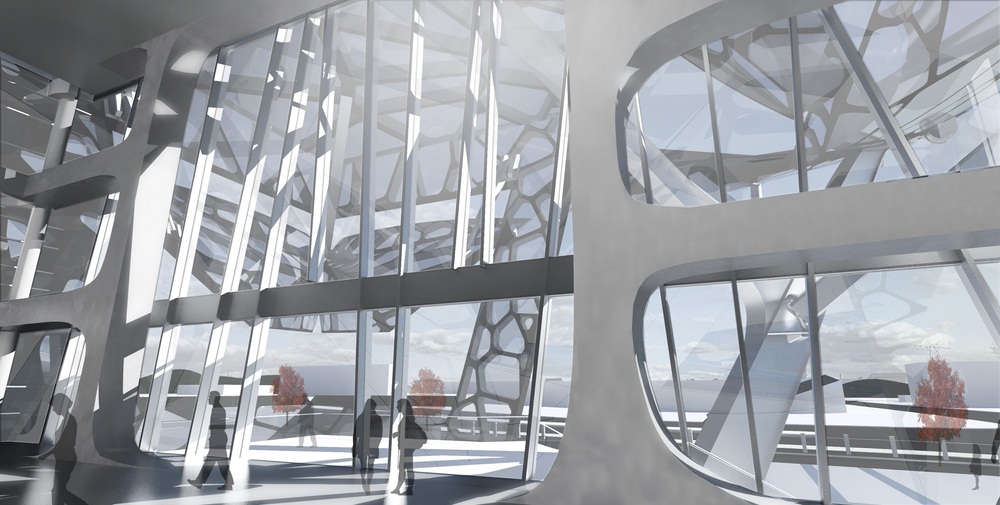

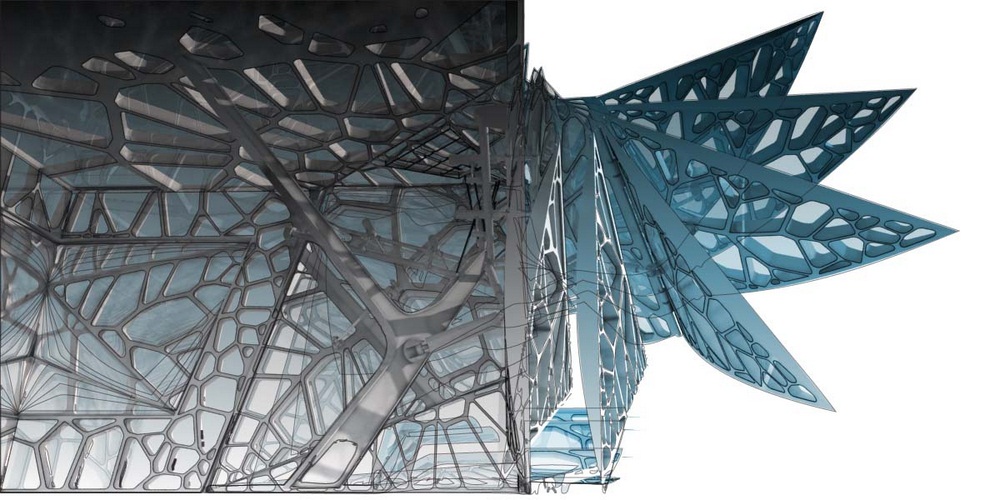

The intricate pattern on the façade is originally inspired by the wing patterns on butterflies or dragonflies. To achieve the systematic and organic nature of the patterns found on the wings of these insects, we used parametric modeling tools to generate and design the façade. The material for the skin is steel and glass. The pattern provides a light but sturdy structure. It conceals and incorporate the hydraulics which move and hold it in place. The result is a beautifully laid out intricate pattern, which allows daylight to penetrate into the exhibition hall and light emanate out into the corporate campus at night.

To bring this design into actuality and assure its functionality and durability, we have been working with renowned international engineering firms on the constructability and procurement process. Their experience has shown how a cross disciplinary effort can increase the efficiency and quality of the product. Kinetic and static structures are separated as engineering services. Engineers in coordination with architect and client will provide a set of system specifications for both static and kinetic structures, similarly to product specification. After the schematic design phase all documents are given to a specialty fabricator with engineering capability to design, fabricate, install and warranty the final product, overseen by the original engineer. This streamline process starts communication early, allowing each team to interject into the process in time to provide their strength and assure the highest quality result.

Client: Zoomlion Heavy Industry & Technology Development Co., Ltd.

Intended Use: Corporate headquarters exhibition center

Architect and Project Designer:

Nonchi Wang

Sam Keville

Parametric Design and Programming:

Qi Su

John Farrace

Digital Modeling:

John Farrace

Sam Keville

Steven Ni

David Van Arsdell

Project Manager:

Luoya Tu

Project Architect:

Yu-I Chan

Kisung Nam

Mechanical Choreographer:

Zhou Yu

Animation:

Shanghai Hertz Design

Intended Use: Corporate headquarters exhibition center

Architect and Project Designer:

Nonchi Wang

Sam Keville

Parametric Design and Programming:

Qi Su

John Farrace

Digital Modeling:

John Farrace

Sam Keville

Steven Ni

David Van Arsdell

Project Manager:

Luoya Tu

Project Architect:

Yu-I Chan

Kisung Nam

Mechanical Choreographer:

Zhou Yu

Animation:

Shanghai Hertz Design

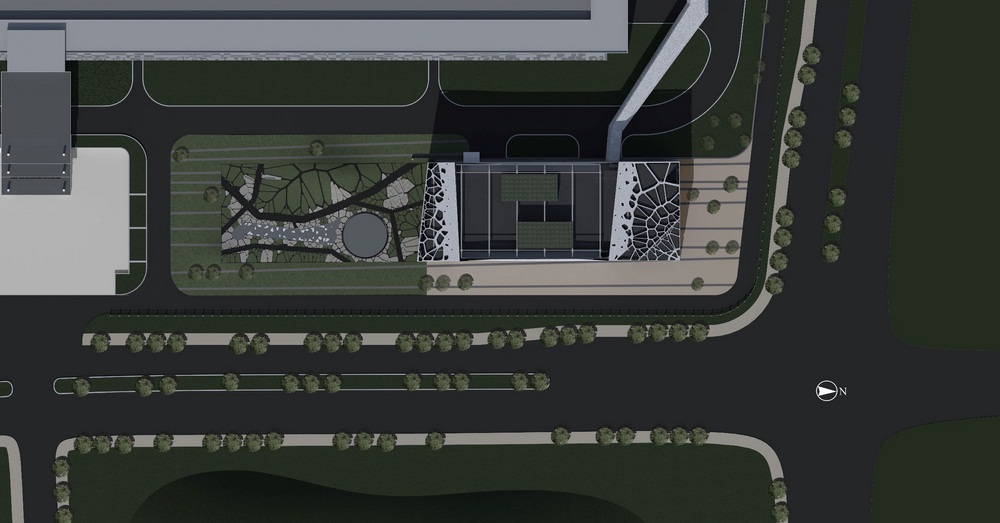

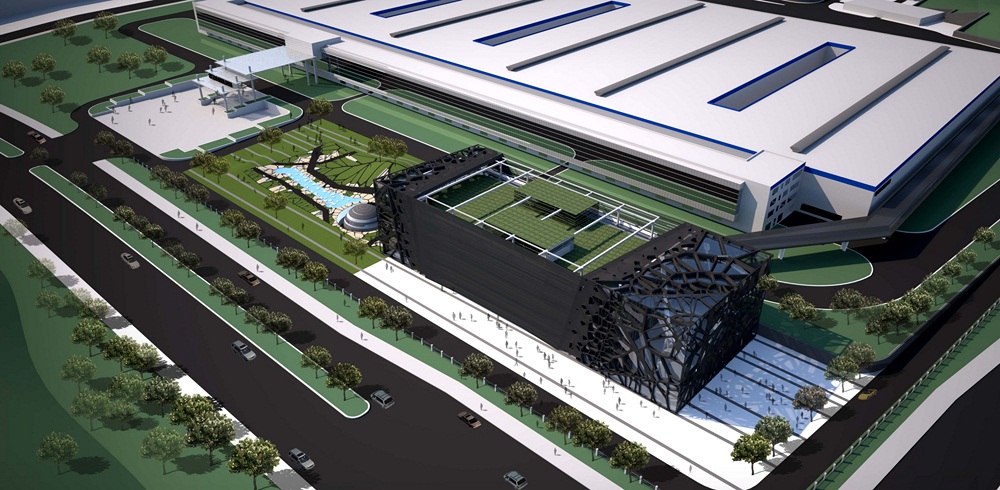

SITE PLAN

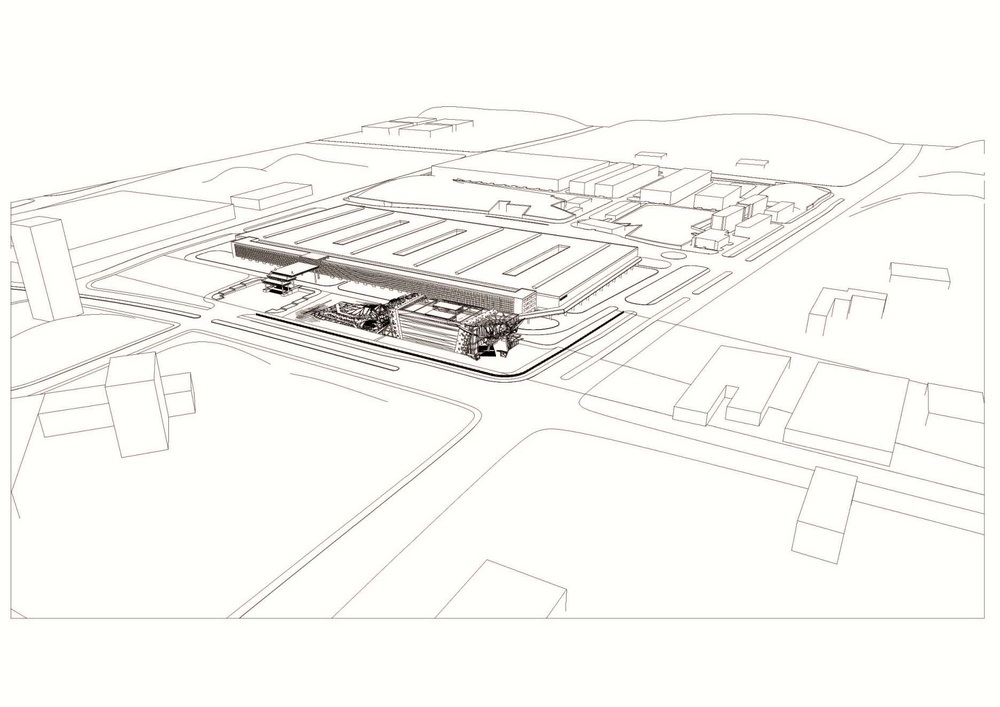

SITE PLAN CHANGSHA SITE

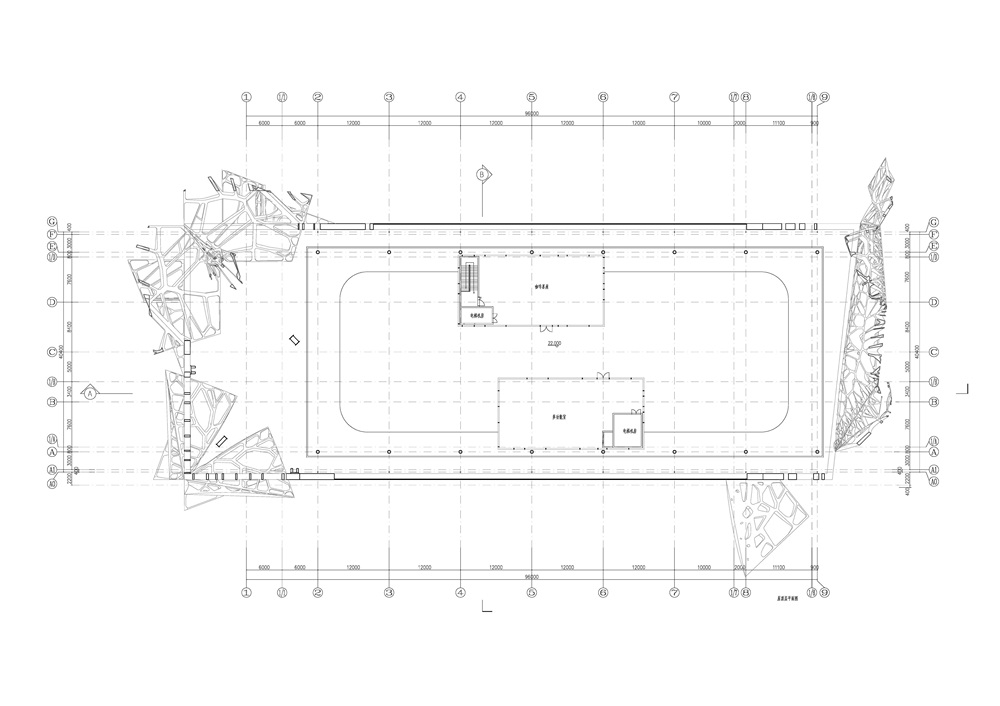

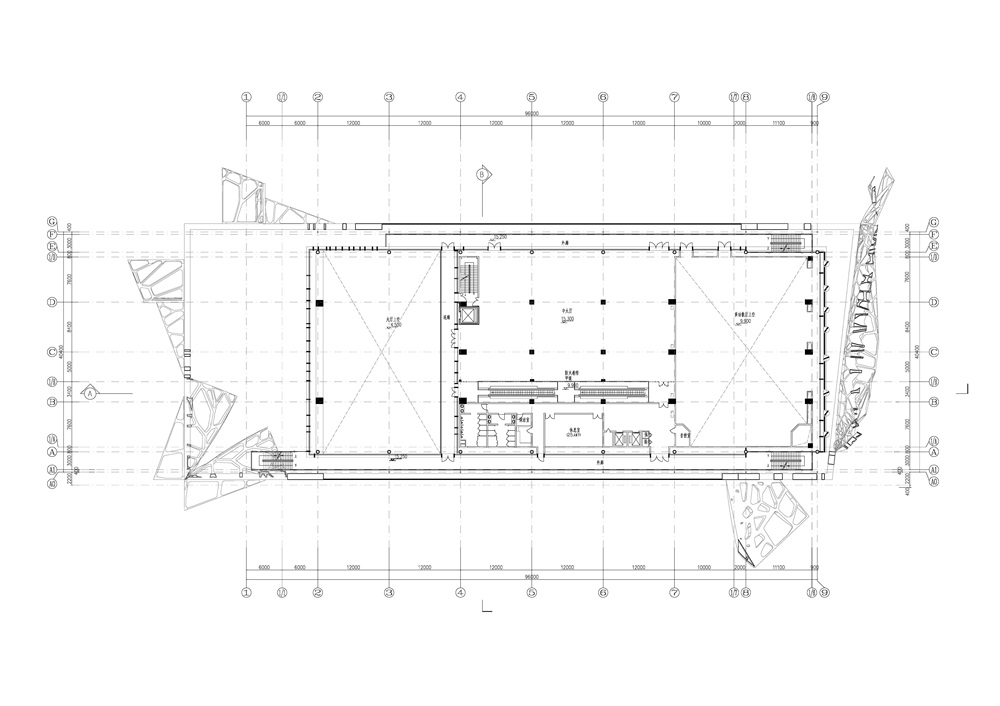

CHANGSHA SITE AFP01-ROOF2

AFP01-ROOF2 AFP01-ROOF

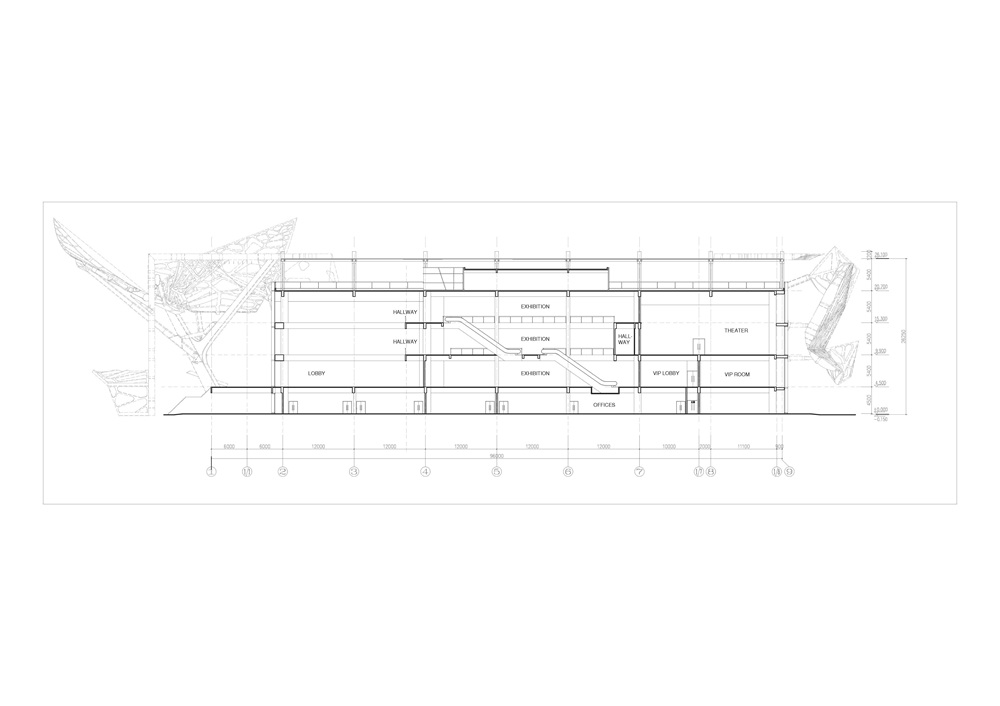

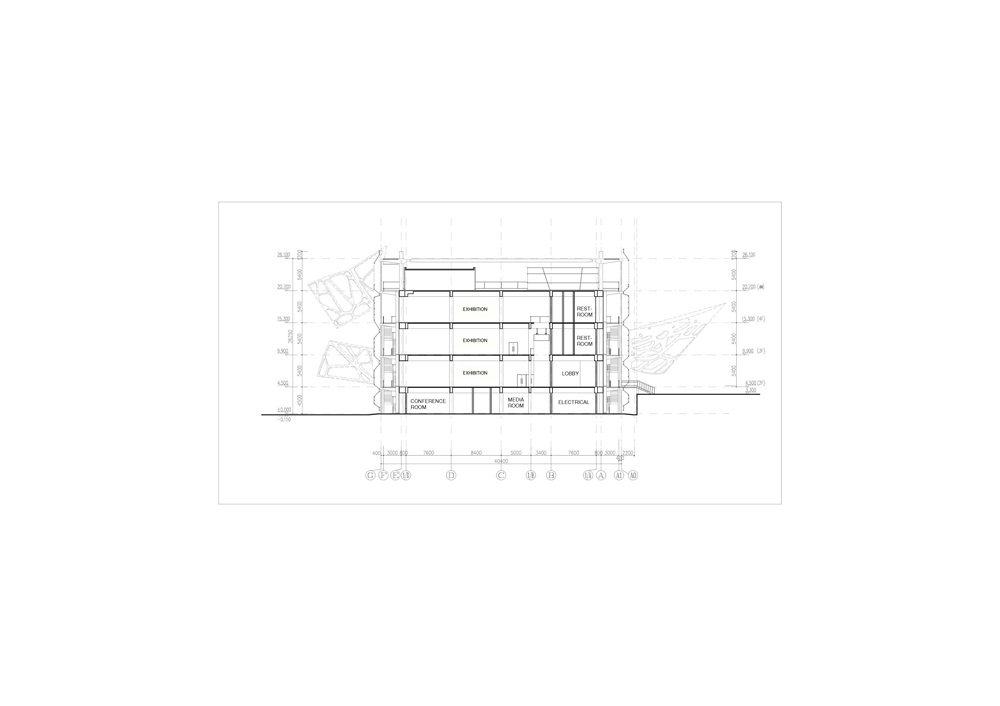

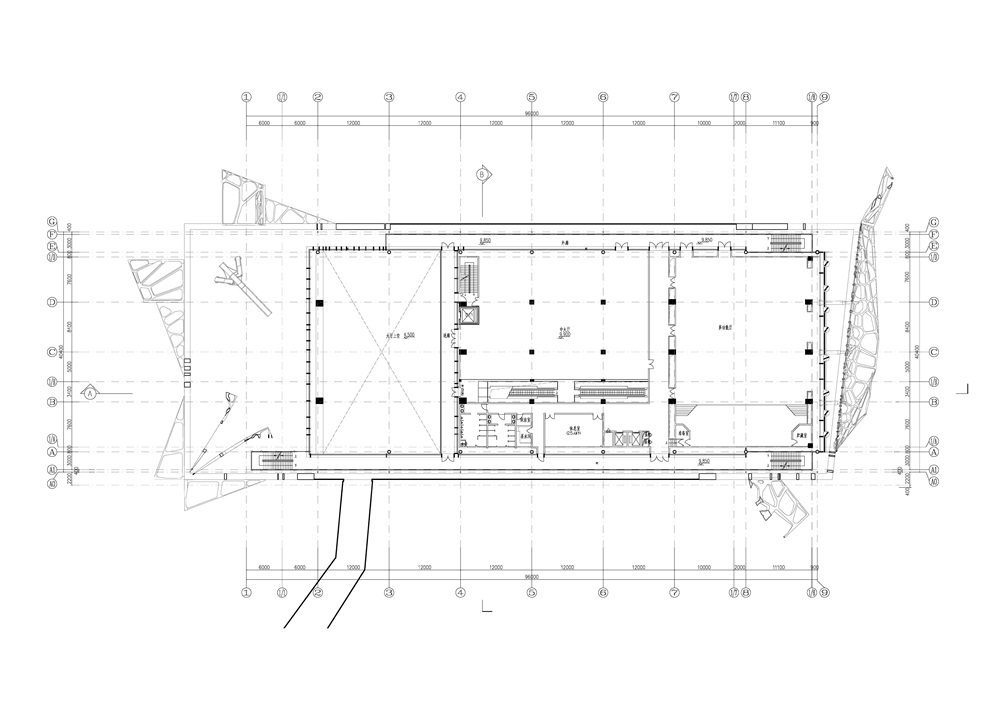

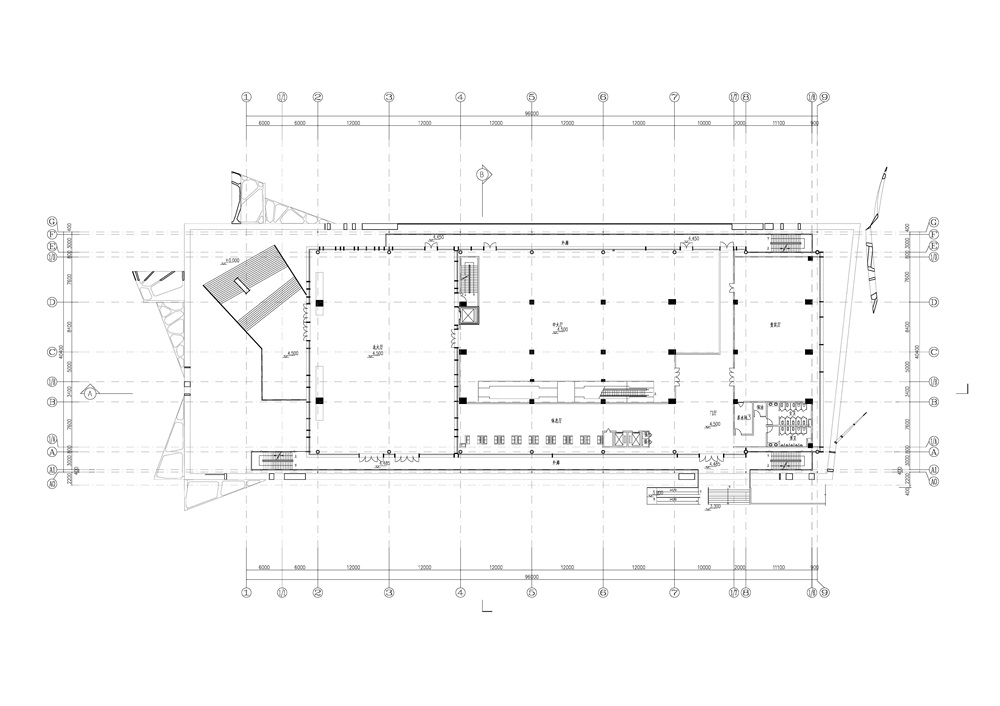

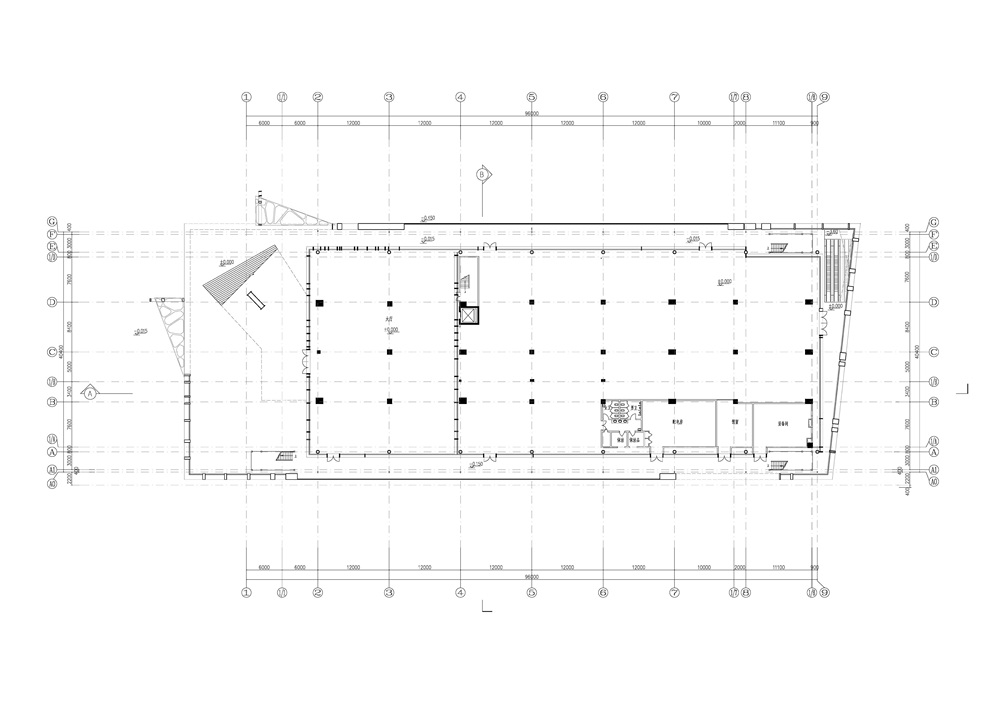

AFP01-ROOF ABS01 – 2

ABS01 – 2 ABS01 -1

ABS01 -1 AFP01-5

AFP01-5 AFP01-4

AFP01-4 AFP01-3

AFP01-3 AFP01-2

AFP01-2 AFP01 – 1

AFP01 – 1 ZOOMLION-08 BIRD EYE VIEW NIGHT

ZOOMLION-08 BIRD EYE VIEW NIGHT ZOOMLION-07 INTERIOR 2

ZOOMLION-07 INTERIOR 2 ZOOMLION-06 INTERIOR 1

ZOOMLION-06 INTERIOR 1 ZOOMLION-05 S7CLOSED

ZOOMLION-05 S7CLOSED ZOOMLION-04 S6OPEN

ZOOMLION-04 S6OPEN ZOOMLION-03 S1OPEN

ZOOMLION-03 S1OPEN ZOOMLION-02 FROGVIEW

ZOOMLION-02 FROGVIEW ZOOMLION-01 BIRDS EYE VIEW DAY

ZOOMLION-01 BIRDS EYE VIEW DAY DIAGRAM 1

DIAGRAM 1 DIAGRAM 1

DIAGRAM 1Zoomlion Headquarters Exhibition Center by amphibianArc from Dezeen on Vimeo.

VIDEO OF ZOOMLION HEADQUARTERS

READ ALSO: ANDREU WORLD / VIDEO / MANUFACTURING DESIGN