Designers Description:

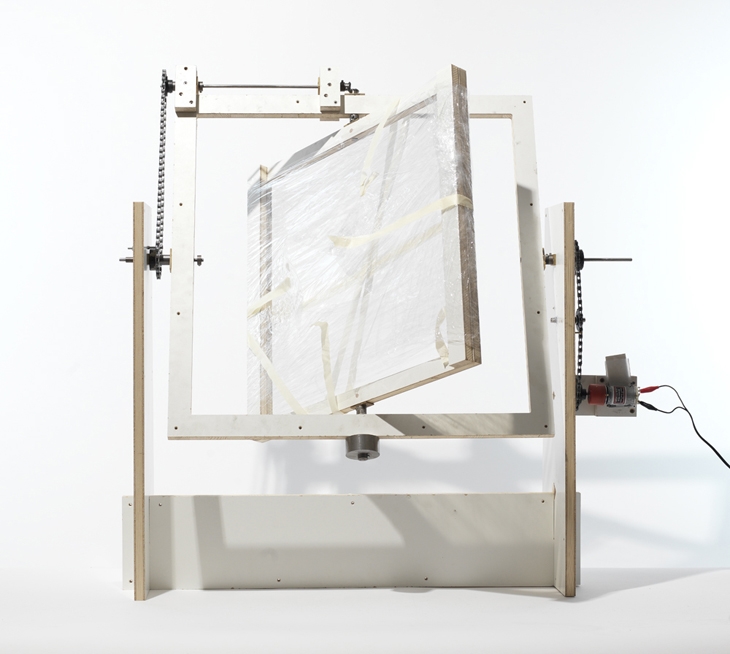

The pendant light »SEAM« is made in a DIY-rotational molding machine. It was originally a test – shape that I designed to experiment with my DIY- rotational molding machine. The lampshade is made from a polymer plaster. A mold is filled with the plaster and than rotated; due to the rotation the plaster sticks to all parts of the mold and a wall thickness emerges. The seam of the molding process is still visible in the product, so are the irregularities of casting process. After some months of experimentation with different shapes and additives such as wood or textiles, I decided to use one test shape to improve the process. I tested all kinds of mixtures of polymer plaster with my test shape and I also did some color experiments. I started to write down everything I did, like laboratory workers do.

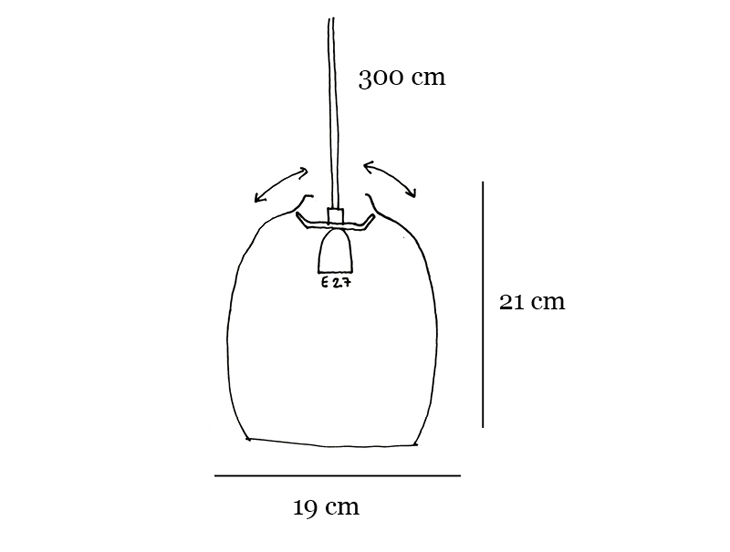

The outcome of my color and material experimentation is a simple lampshade: The molding process compromises three steps with different layers and different colors. The drops inside the lampshade refer to the movement of the machine. The lampshade comes in different colors: green, white and red. It has a smooth surface on the outside, it is sanded and covered with a protective layer of vaseline. Because of the irregular material thickness, the lamp needs a special fixture that enables the user to adjust the lampshade. The fixture is made from sandblasted plexiglass. The special fixture also determines the form of the lampshade: a bigger hole is necessary at the top of the shade in order to adjust the lampshade, the light passes through. The fixture works as a diffusor.

THE SEAM LIGHTS IN MILAN AT »MOST« BY TOM DIXON

THE SEAM LIGHTS IN MILAN AT »MOST« BY TOM DIXON THE SEAM LIGHTS IN MILAN AT »MOST« BY TOM DIXON

THE SEAM LIGHTS IN MILAN AT »MOST« BY TOM DIXON THE SEAM LIGHTS IN THE MAK IN VIENNA, AT THE EXHIBITION »NEW NOMADIC FURNITURE«.

THE SEAM LIGHTS IN THE MAK IN VIENNA, AT THE EXHIBITION »NEW NOMADIC FURNITURE«. SKETCH BY ANNIKA FRYE

SKETCH BY ANNIKA FRYE ROTOMOLDING MACHINE

ROTOMOLDING MACHINE SEAM BY ANNIKA FRYE

SEAM BY ANNIKA FRYE SEAM BY ANNIKA FRYE

SEAM BY ANNIKA FRYE SEAM BY ANNIKA FRYE

SEAM BY ANNIKA FRYE SEAM BY ANNIKA FRYE

SEAM BY ANNIKA FRYESEAM-ROTOMOLDED LIGHT from Annika Frye on Vimeo.

SEAM by Annika Frye

READ ALSO: STUDIOLAV YOUNG TALENT DESIGNERS OF THE YEAR NOMINATED FOR THE EDIDA AWARD